Avonmouth Batching Plant

Balfour Beatty

52 weeks

£3.8m

A purpose-built facility to manufacture concrete ring segments that will form the main cooling tunnels for the new Hinkley Point C nuclear power station in Bridgwater. When operational the facility can produce 160 segments a day and will run 24/7. Each segment measures 6m x 4m and weighs several tonnes. A total of 48,000 segments are needed to build the new cooling tunnels that run out into the Severn Estuary. It is understood the facility will go on to produce the tunnel segments for the new HS2 high speed rail link that is underway between London and Birmingham.

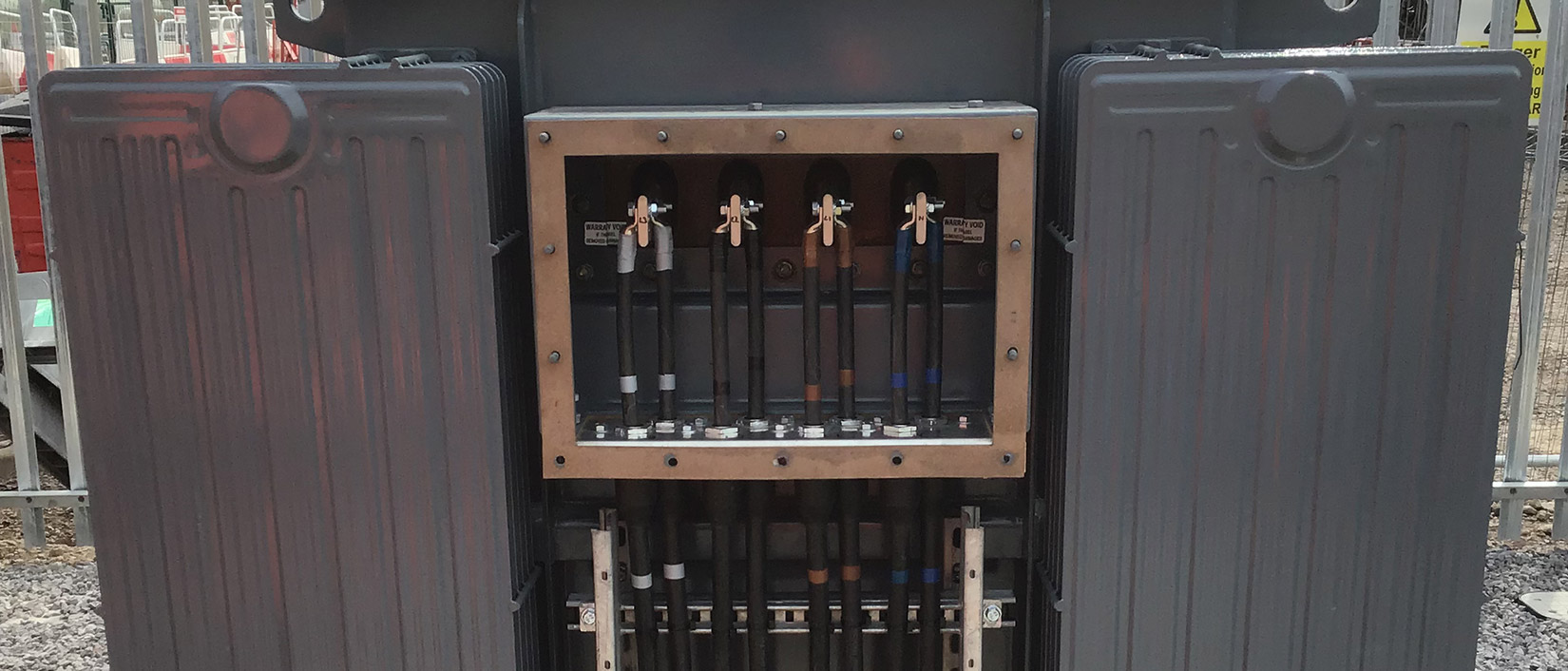

Electrically the building has its own diverse HV package substations and main LV distribution panels high level perimeter ladder rack containment distributes sub-main cabling to local distribution boards. High-level Tecton LED lighting system illuminates the main production area, with emergency lighting central battery system providing safety lighting in the event of a power outage.

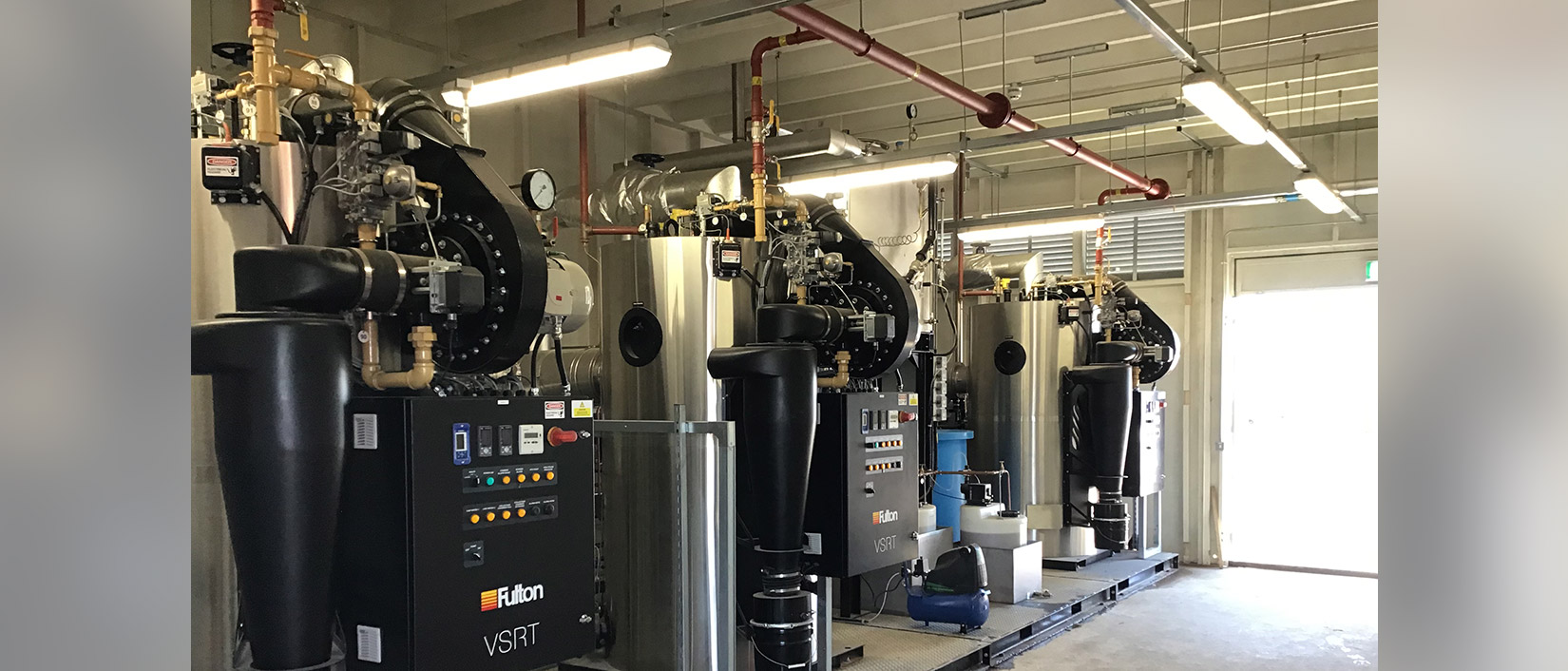

Mechanically Calor gas provides the fuel for three number steam generators (in an N+1 configuration). These supply the heat for the curing process of the segments, with a compressed air system operating much of the process plant.

Standard welfare facilities in the corner of the building provide staff rest areas and changing facilities.

Aces also (with the assistance of its supply chain members) supplied and erected all secondary steel structures required for plant and flue support.